GEC solutions to accelerate the digital transformation

The digitalisation of Germany’s manufacturing industry is progressing too slowly. How, though, is it possible to speed up the digital transformation and achieve concrete results faster? And how can companies improve their flexibility and productivity while also saving energy?

At HANNOVER MESSE, German Edge Cloud (GEC) will have the answers you are looking for in the form of its ONCITE DPS (Digital Production System). GEC makes digitalisation scalable – from transparency as a basic requirement and AI-supported processes all the way through to end-to-end factory digitalisation. Using your company’s precise current situation as a starting point, we will increase your level of digitalisation and help improve your productivity, sustainability and energy efficiency.

As part of the Friedhelm Loh Group, GEC will be represented along with its sister companies Rittal, Eplan and Cideon at the joint stand E06 in Hall 11, providing a combined showcase of solutions for the future of factories.

Discover just how much digitalisation can do for your company

Don’t delay – contact us today to arrange

an appointment with our team of experts!

Experience digitalisation first hand!

Our live showcases at HANNOVER MESSE 2024

Connected ecosystems – the future of the automotive sector

Industrial metaverse – diving into the virtual factory of the future

Sustainability and energy efficiency – leveraging savings potential

Industrial AI – the smart factory

Showcases

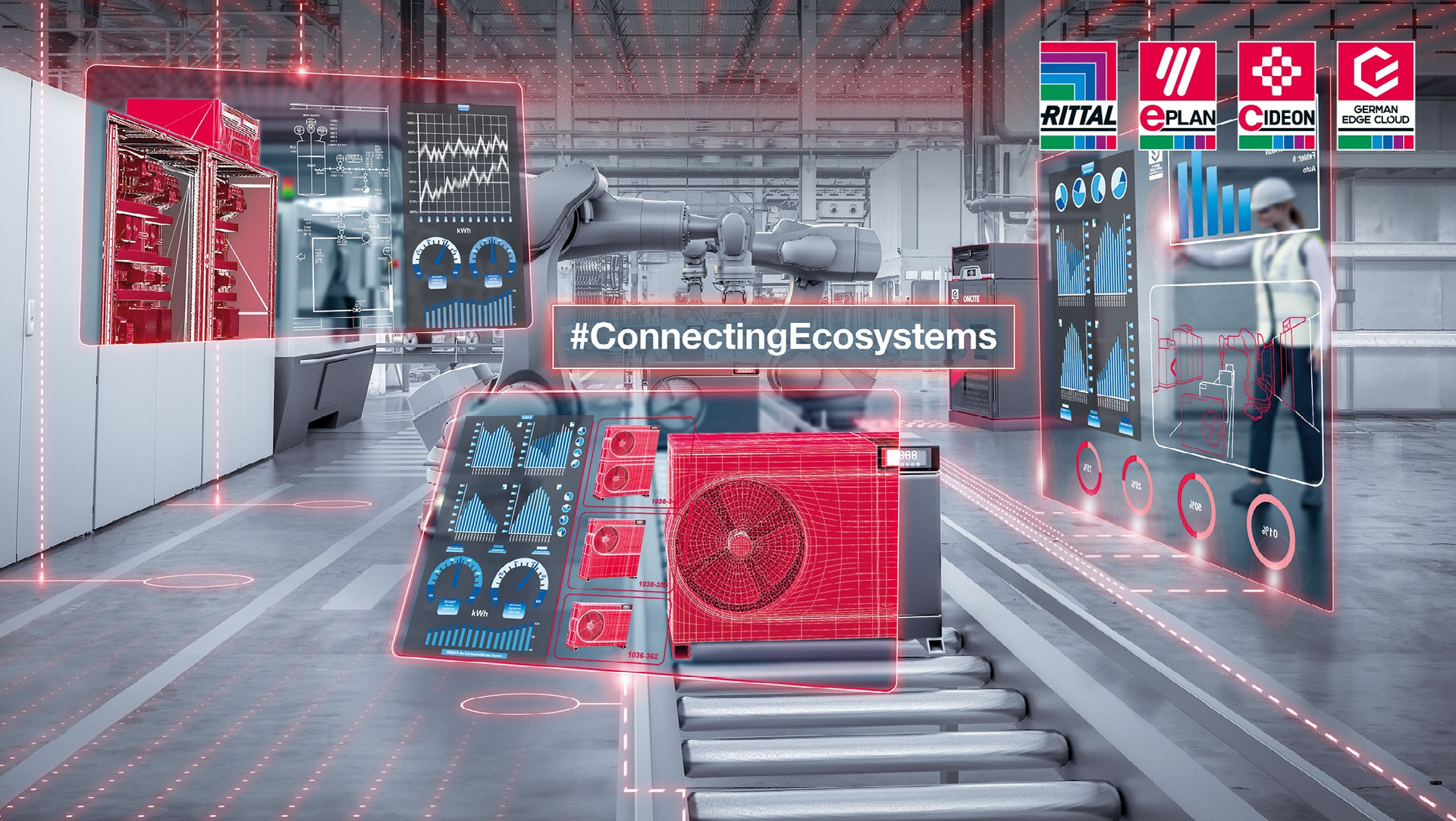

Connected ecosystems – the future of the automotive sector

GEC is opening the door to connectivity in the automotive sector and showing how ecosystems can be appropriately combined, for example via a CX-Gateway link and data transfer into various ecosystems.

At the trade fair, GEC will be presenting an application scenario for seamless production documentation in a supplier’s smart press shop. This is made possible by the Schuler Group’s Digital Suite, which is based on the Catena-X-certified “ONCITE DPS Track&Trace” service. GEC will also be using the ONCITE CX-Gateway to demonstrate the wide-ranging possibilities of secure, sovereign data exchange throughout the entire value chain between the supplier and the plant of an automotive OEM. For instance, all relevant data can be made available for Catena-X or other ecosystems such as SupplyOn (e.g. for a PCF calculation and ESG report).

Industrial metaverse – diving into the virtual factory of the future

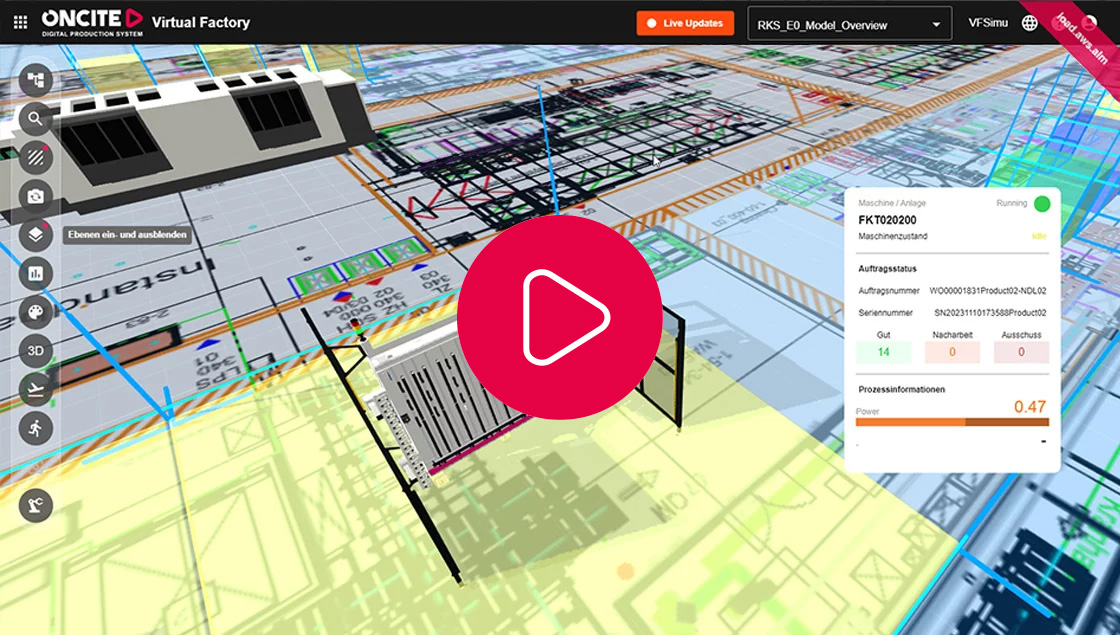

With the ONCITE Virtual Factory and the digital twin as the key technology, it is possible to take a big step towards the industrial metaverse – the link between the real and virtual production worlds.

Using a 3D visualisation of your actual factory, you can gain a transparent insight into all operating processes and a detailed depiction of the data situation in production. Thanks to highly integrated data management, real production data can be visualised and evaluated in near-real time using 3D images of the factory (assets, processes and interactions). This makes it possible, for example, to quickly identify and resolve problems.

Sustainability and energy efficiency – leveraging savings potential

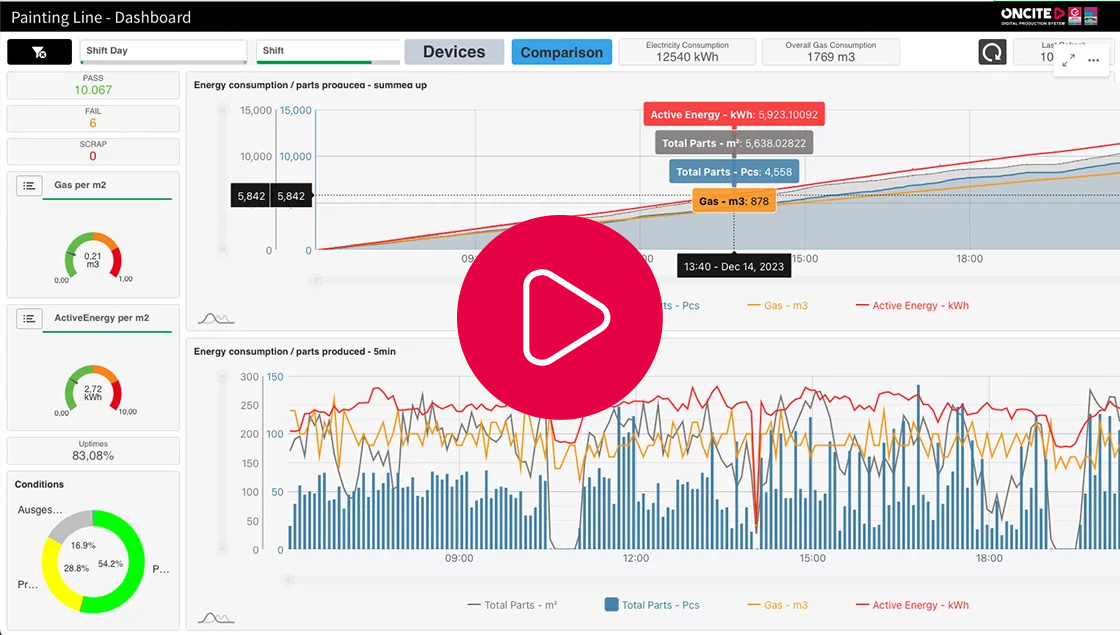

The energy transition calls for fundamental changes in industry. The transformation to smart production is becoming an important task, as is ensuring transparency regarding data streams, including energy data.

The ONCITE DPS provides solutions for monitoring and optimising energy consumption in production. By monitoring energy and analysing usage data, you can identify savings potential and develop more sustainable production processes that will help you achieve cost savings and reduce your carbon footprint.

At the trade fair, GEC will be offering a live insight into a paintshop at the Rittal plant in Haiger and highlighting possible ways of saving energy.

Industrial AI – the smart factory

Artificial intelligence has arrived in industry. AI is accelerating the digital transformation and making a massive contribution to ensuring successful widespread digitalisation in industry. It is already offering big benefits – when it comes to detecting errors and boosting production, for instance.

At HANNOVER MESSE, GEC will be demonstrating a variety of AI solutions in the areas of generative AI and visual inspection.

Google Cloud and GEC showcase Generative AI solution for intelligent assembly worker assistance

Assembly workers now benefit from an intuitive GenAI assistant. We are implementing an AI solution for intelligent worker assistance based on Google Cloud solutions. At the Google Cloud booth, we will be demonstrating, for example, how this solution can facilitate the assembly of various custom-made control cabinets.

For example, the AI-based assistance offers context-sensitive support and instructions to guide workers in their tasks. The AI can also suggest or support test sequences to ensure that the assembly has been carried out correctly and that the control cabinet works as expected.