The smart factory becomes reality with AI

With the AI solutions from ONCITE DPS, you can significantly accelerate the digital transformation in your factory, increase quality and reduce the workload

Artificial intelligence is the key to accelerating the digital transformation in industry and makes a significant contribution in optimizing production times, improving quality and saving costs. With easy-to-use software modules from ONCITE DPS, you can successfully integrate AI into your digitalization strategies and easily solve challenging tasks without in-depth technological knowledge of your own. You benefit from greater agility, increased efficiency and quality, as well as reduced workload. With the AI solutions of the ONCITE Digital Production System, you receive easy-to-integrate AI modules with which you can implement valuable support services and significantly optimize production. Solutions for visual inspection (Visual AI) and more intuitive operations in assembly processes through AI-supported assistance (Gen-AI) have already proven themselves in action.

Visual AI for visual quality inspection

With the use of AI, more and more production processes are being optimized and working environments are becoming more intuitive. Vision AI in particular is becoming increasingly relevant in production processes and especially in the area of QA. It reduces throughput and rework time and increases the quality of products, while at the same time reducing the use of resources.

Functionalities

through the use of pre-trained models

Benefits

AI-supported quality inspection - becoming a standard in production

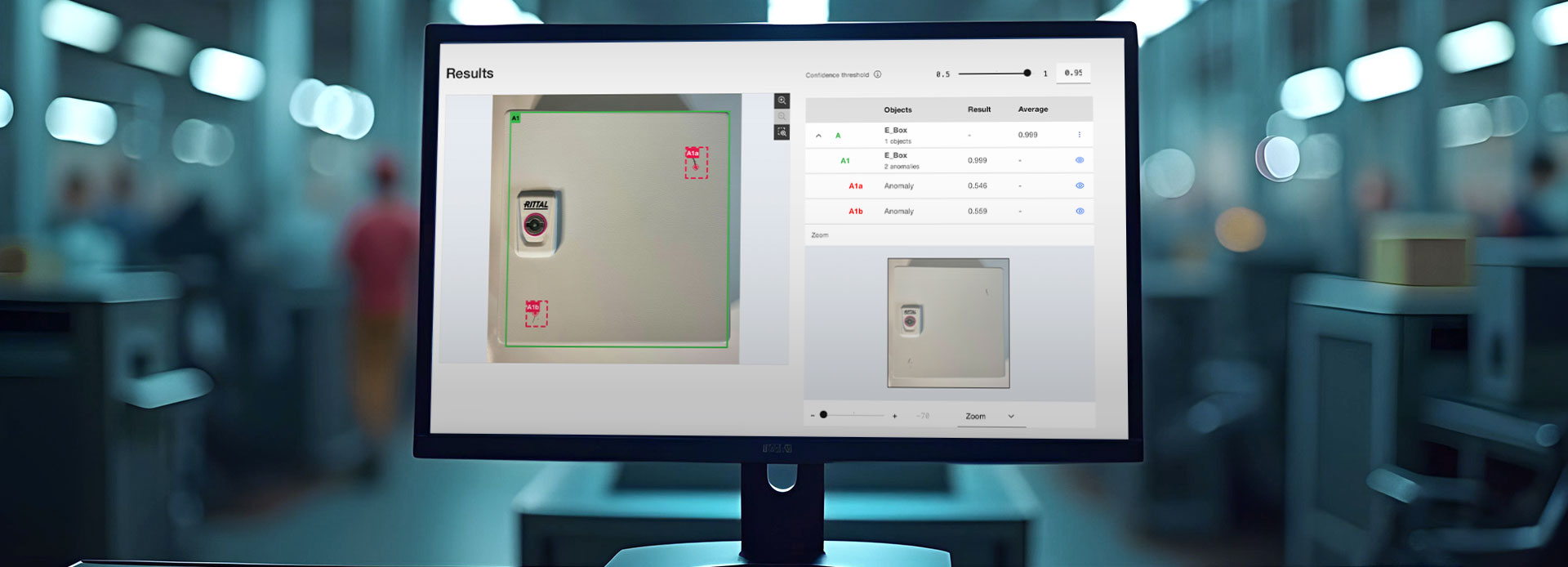

The joint Vision AI solution from German Edge Cloud and IBM, which is very easy to integrate, brings all the benefits of AI-supported visual quality inspection. Seamless integration of additional plug-and-play hardware components such as cameras, edge computers and switches enables fully automated quality control of workpieces, including the detection of anomalies, defects and scratches or the inspection of assembly and cabling processes.

The AI is trained with photos, continues to learn and therefore delivers increasingly better results. The early, reliable and permanent detection of quality problems significantly reduces the costs of reworking or rejects, for example.

AI use cases: Successful in use

When the eye gets tired, Visual AI remains sharp and alert.

Visual AI improves quality control in the industry through precise and continuous defect detection. With the implemented solutions in the area of QA, material surfaces are checked for damage and the completeness of accessories is checked fully automatically with AI support during the subsequent packaging process.

Achieved Results

Test AI solutions now! Request a demo!

Arrange a demo now and see the benefits of our software modules for yourself.

GenAI as intelligent assistance

There is great potential for optimizing your factory, for example, by implementing more intuitive workstations with intelligent worker assistants, especially when assembling customized items. In the past, employees had to laboriously leaf through assembly instructions, which cost time and could lead to errors in the process. Now, with the GenAI module of the ONCITE DPS, you get an intelligent and intuitive ChatBot that acts like an assistant and automatically and dynamically compiles the instruction templates to suit the assembly situation.

Functionalities

Benefits

Generating new knowledge dynamically from data with Gen AI and making it tailor-made available

Generative AI provides context-sensitive support and instructions to guide your employees through their tasks. It accesses structured and unstructured data sources to extract relevant information for the process. The solution integrates descriptions, CAD drawings and contextual information and guides employees seamlessly through every step of the assembly process.

AI use cases: Successful in use

Automatically combine knowledge with GenAI and provide it as a tailored solution

For example, GenAI can make assembly easier for the worker in the case of different individual assemblies. Overall, the solution aims to improve assembly through the use of AI-supported assistance by supporting the worker with precise instructions and recommendations to make the process more efficient and error-free.

Manufacture smarter now! Request a demo!

Arrange a demo now and see the benefits of our software modules for yourself.