Transparency: Key factor for production efficiency

Gain a 360-degree view of your production with ONCITE DPS - for faster fact-based decisions and increased productivity.

Customers are increasingly demanding customized products, shorter delivery times and the highest quality. Transparent production enables precise analysis in order to optimize the key success factors such as resources, energy consumption and machine utilization, but also to eliminate existing inefficiencies. The ONCITE DPS Transparency software module provides you with a near-real-time and visual view of all operating data (production, machine, process and IoT data). The transparent overview and analysis of data gives you in-depth insights into the production processes to identify weak points and optimization potential, which leads to error minimization and more efficient production.

Functionalities

Benefits

Get a detailed overview of your production - request a demo!

Arrange a demo now and see the benefits of our software modules for yourself.

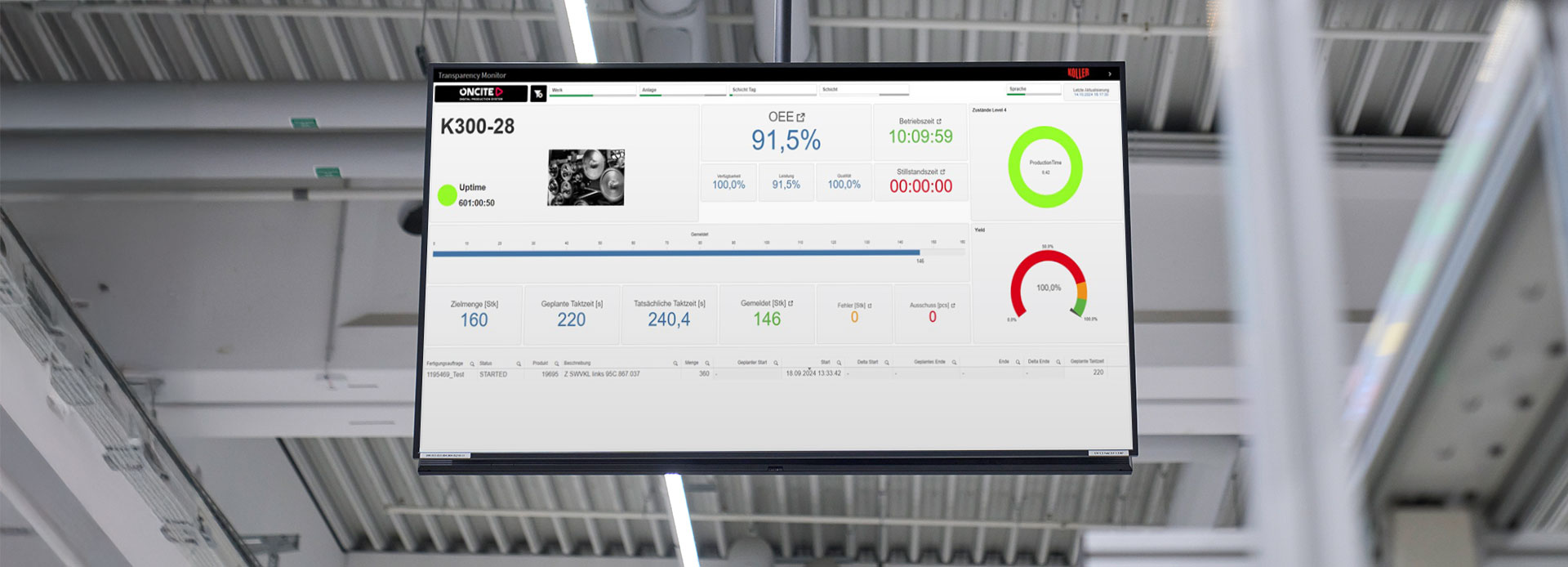

Koller has a clear view

Comprehensive transparency and real-time data availability

Koller Kunststofftechnik GmbH produces injection-molded parts for the automotive industry. With the Transparency software module from the ONCITE Digital Production System (DPS), the company can monitor its manufacturing processes in near real time. This enables fast and reliable data-based decisions. A dashboard provides valuable insights into plant conditions, production KPIs and output, for example. The solution also enables the automated calculation and analysis of overall equipment efficiency (OEE). Real-time transparency is the lever for faster error analysis and precise adjustments for process optimization. The ONCITE DPS was implemented in just three days.

- Complex manual processes replaced by digitization

- Reliable insights through valid data

- Fast and realistic assessment of the current production situation

- Preventive action reduces downtime

- Overall OEE improved and output increased

Achieved Results

With “Transparency” towards a digital production twin

The smart factory is transparent and traceable

The Transparency software module of the ONCITE DPS gives you valuable insights into all production and process data as well as comprehensive control over your ongoing factory operations. With the virtual 3D view of the real factory (Virtual Factory), you can also visualize all production processes as a digital production twin in near real time.

- Map the status of production quickly and easily in 3D.

- Create individual dashboards quickly and easily

- Gather, evaluate and display data (from sensor values to ERP postings) seamlessly and promptly

- Generate historical representations - e.g. to identify disruptive factors.

- Create correlation analyses and detect anomalies.

- Carry out in-depth data analysis: from simple aggregation for creating reports to data science applications.

Optimizing

production processes

Increasing

transparency

Experience it for yourself! Request a demo now!

Arrange a demo now and see the benefits of our software modules for yourself.