Customer MES and ONCITE DPS in sync

- Flexible hybrid operation on edge and cloud

- Step-by-step migration of existing MES solutions to the ONCITE DPS technology platform

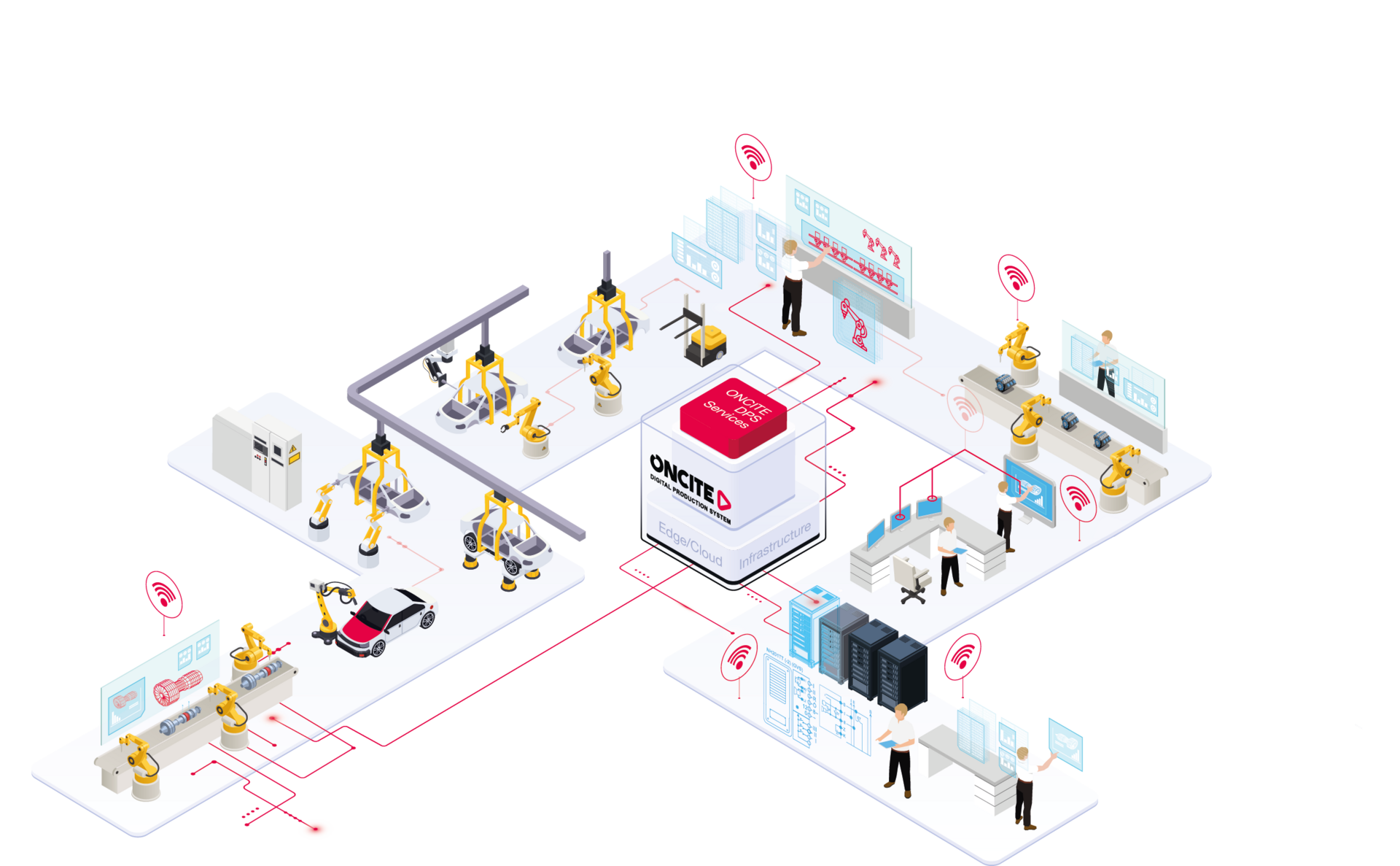

The ONCITE Digital Production System offers fast, secure networking of your production, state-of-the-art data management and maximum production transparency.

ONCITE DPS is the reference architecture for smart factories, having been purpose-developed and optimised for the use of IIoT-compatible devices, digitalisation and industrial application software in line with Industry 4.0 principles. It links the previously separate core components of digital production with a flexible microservices architecture: Agile production management with MES and MOM functions, Industrial IoT as the database and low-code development for simple app creation. All this plus edge computing for sovereign data processing. What’s more, ONCITE DPS is a highly relevant node (integration platform) within secure digital ecosystems (such as Catena-X).

Establish intelligent processes for more efficiency and greater plant availability

Ensure comprehensive production documentation

Create production transparency and make fact-based decisions

Respond quickly to market changes with scalable and modular applications

Use integrated intralogistics for greater productivity and delivery reliability in your factory

Manage data better and more securely

Learn more about the unlimited possibilities of the ONCITE DPS now!

ONCITE DPS scores top marks in these areas:

The result is a highly flexible reference architecture for smart manufacturing, comprised of a technology and digitalisation platform plus a host of services and bespoke, easy-to-integrate functions to boost the efficiency of your smart factory.

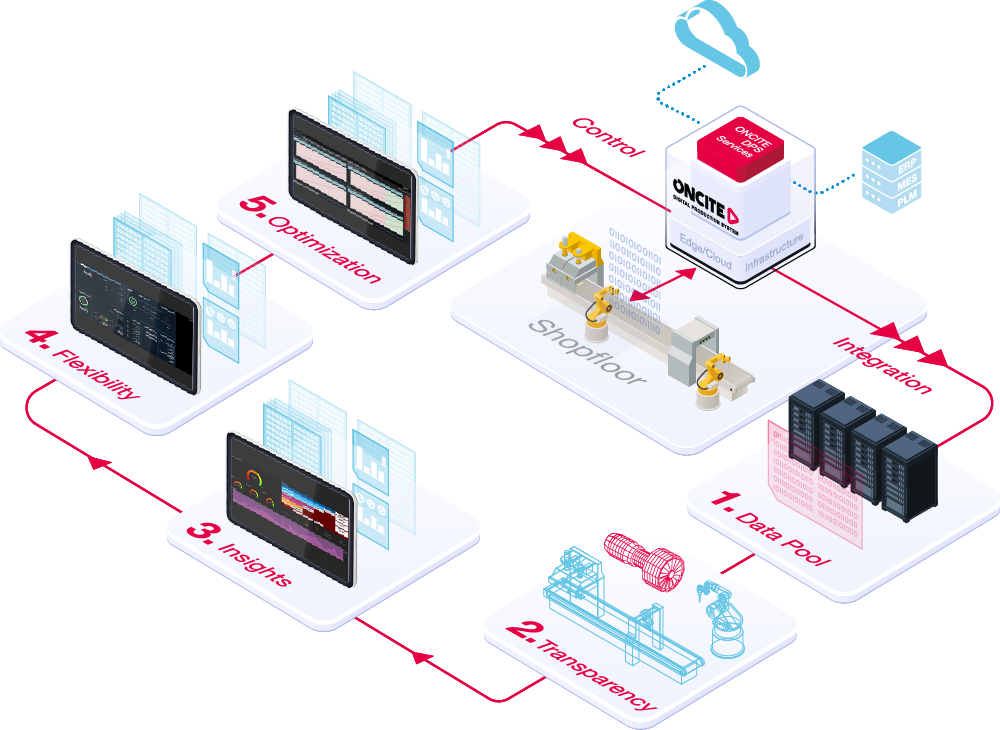

Data collection and management allow you to exploit optimisation potential that was not visible before.

Data collection and management allow you to exploit optimisation potential that was not visible before. Machines become more efficient, machine status can be monitored more comprehensively, and unplanned downtimes are avoided. Use the possibilities of the online validation of production and process data to significantly increase your product quality.

For example, increased transparency regarding your energy consumption helps you respond rapidly to events. By analysing complex production processes in quasi real time and making decisions on this basis, you can ramp up your productivity and energy efficiency.

Boost your productivity, agility and energy efficiency

With the services from the ONCITE Digital Production System, you ensure that you get the data workflows and processes digitized. At the same time, you obtain optimal transparency of your production. Based on a highly effective, qualified data pool and the resulting insights, you develop a rule-driven, intelligent and data-driven production management (Closed Loop Control). This enables you to optimize your production along the value chain.

The cloud-native services of the ONCITE Digital Production System (DPS) help you meet your requirements as needed, particularly in established structures. We take into account the fact that many factories use existing IT solutions (such as MES) which work extremely well and should continue to be used. We also support you with an effective migration concept. On the one hand, this allows you to install the ONCITE solution concept alongside your existing IT/OT infrastructures and, on the other hand, to benefit from the advantages of the ONCITE DPS as you go.

Maximum production transparency and increased optimization potential

At its Haiger plant, Rittal consistently manufactures keeping with Industry 4.0 standards. The world’s leading system provider for enclosure technology, power distribution, climate control, IT infrastructure, software and service...

Increased product quality with continuously improved overall system efficiency

German Edge Cloud (GEC) is cooperating with Schuler, a machine and plant building company. In this context, Schuler is offering a track-and-trace solution for press plants within the Digital Suite...