German Edge Cloud “Best in Class” in PAC Radar

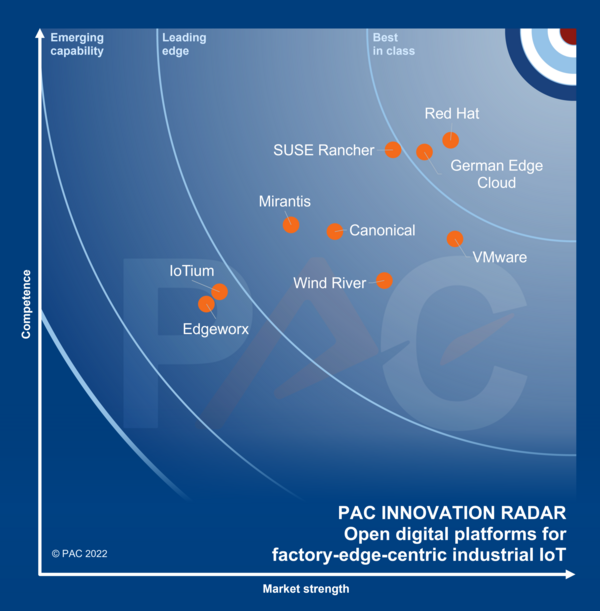

PAC has ranked German Edge Cloud (GEC) as "Best in Class Open Digital Platform for factory-edge-centric industrial IoT" in Europe. In this segment, only GEC and IBM/Red Hat were rated "Best in Class". According to PAC, the unique capabilities of GEC derive from its merging of domain know-how in both manufacturing and IT. For the PAC INNOVATION RADAR "Open Digital Platforms for the Industrial World 2022", the market analysis and consulting company evaluated 79 relevant platform providers.

Limburg/Eschborn, 20th September 2022 – The analysts examined the platforms and capabilities of relevant providers in the segment and applied the principal criteria “Competence” and “Market strength” to plot their standing on its familiar RADAR graph. With the new ONCITE Digital Production System, German Edge Cloud secured a leading position in the “Best in Class” group in both main clusters. Last year, the industrial IoT specialists from the Friedhelm Loh Group were named “Hidden Champions”. They were already positioned among the frontrunners in the evaluation of competence, and have now recorded a giant leap forward in terms of market strength.

Open, Kubernetes-based factory-edge software platforms are the key to smart production – that is the conclusion of the analysts from Pierre Audoin Consultants. In their latest study, they explain that low-code capabilities, micro-service architectures and container technology lay a technical foundation for the necessary agility in application development.

“We are very pleased to be at the top of the PAC radar,” says Dieter Meuser, CEO of Digital Industrial Solutions at GEC.

“But our progress in the market was only possible together with our customers. I would like to thank them for their trust in GEC and exciting projects.”

According to Meuser, the reasoning laid out by PAC in its evaluation confirms GEC’s own practical experience: “Heterogeneous technologies are still widespread in today’s factories, with multiple systems, devices and IT/OT infrastructures. Their networking and contextualisation of the data, in other words, understanding of the function of data in the manufacturing process, requires considerable factory experience.” Solutions with high levels of agility for IIoT-assisted control are crucial if production is to become genuinely smarter. “Micro-services achieve this with significantly reduced development costs compared to an inflexible, monolithic software architecture.”

Five success factors for IoT in the industry

PAC cites five essential aspects which contributed to its evaluation of German Edge Cloud: First, GEC possesses strong factory expertise and, with the ONCITE Industrial Suite, offers a dedicated, cloud-native application portfolio for the factory edge. Second, GEC is the first strategic partner of Red Hat for the digital factory, and the ONCITE Digital Production System leverages Red Hat OpenShift as a core technology.

Based on these two aspects, GEC is according to PAC the only vendor in the market which combines factory expertise and container/Kubernetes know-how to offer a standardised Kubernetes platform dedicated to the industrial world.

Third, the analysis confirmed the growing market resonance of GEC, with several relevant client engagements in the automotive sector, among others. One example: In the Smart Press Shop in Halle, Schuler and GEC are optimising the production of body parts for Porsche using track-and-trace down to the level of individual component data. In addition, PAC noted strong momentum for GEC’s offering at the Hannover Messe in 2022.

Fourth, GEC draws synergy benefits from the experience and industry presence of its sister companies in the Friedhelm Loh Group. “Rittal supplies system technologies for the infrastructure in almost all industries. Eplan is the proven standard when it comes to the engineering of electrical systems, and Cideon can contribute broad experience in CAD/CAM and PDM/PLM. Our joint domain knowledge enables us to achieve faster results in the networking of plant, product data and production ecosystems,” Meuser explains.

Finally, PAC sees GEC as a strong open-source and ecosystem player in the German manufacturing industry. GEC is one of the co-founders of the GAIA-X project and one of the driving forces behind Catena-X, which fosters open data exchange along the entire automotive supply chain.

The best-in-class platform

The ONCITE Digital Production System combines previously separate core components of a digital production environment in an integrated system: Intelligent production management with MES and MOM functions, industrial IoT as a database, and low-code capabilities for simple application development. On top of this, edge computing meets all demands regarding sovereignty in data processing. The result is platform and application functionality in an integrated solution with modern, flexible architecture.

Here you can find the complete study from PAC:

https://gec.io/newsroom/downloads/