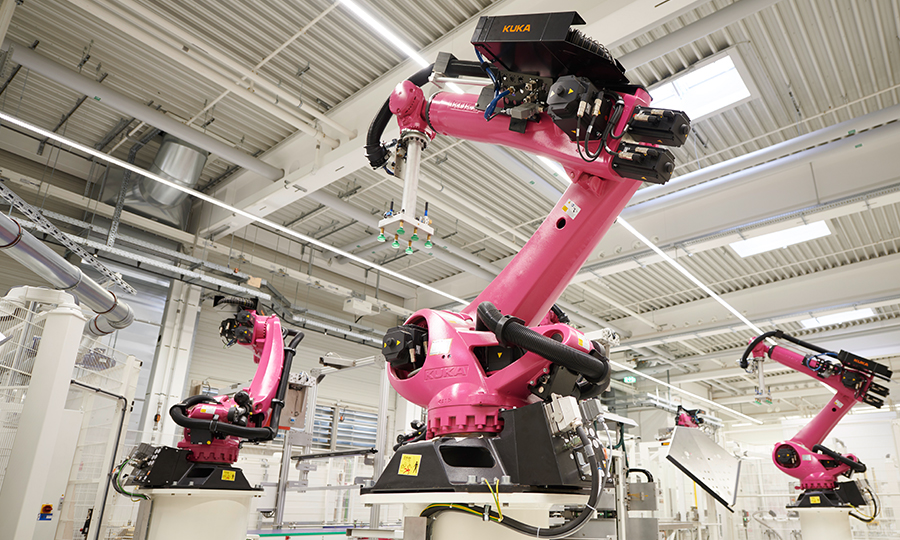

Rittal

At its Haiger plant, Rittal consistently manufactures keeping with Industry 4.0 standards. The world’s leading system provider for enclosure technology, power distribution, climate control, IT infrastructure, software and service...

Because every company is different, so are their requirements and the levels of digitalization they need in their factories. “Smart factory apps" based on microservices architectures avoid the expensive use of monolithic IT systems and are considerably ahead of them in terms of openness and adaptability. Software services can be easily integrated and always used in coexistence with existing applications. This allows you to design your smart factory in a demand-oriented and cost-effective manner.

Learn more about the unlimited possibilities of the Smart Factory Apps now!

At its Haiger plant, Rittal consistently manufactures keeping with Industry 4.0 standards. The world’s leading system provider for enclosure technology, power distribution, climate control, IT infrastructure, software and service...

German Edge Cloud (GEC) is cooperating with Schuler, a machine and plant building company. In this context, Schuler is offering a track-and-trace solution for press plants within the Digital Suite...

The path to a customised smart factory

Intelligent production

The aim is to increase productivity using secure information about machine states, OEE, output/utilisation and error causes. When production conditions can be visualised in near real time, it is possible to react proactively to changes and problems.

Through a continuous increase in system networking and the use of precisely tailored IoT-based solution modules, almost all the production and process-relevant data of the machines and states can be obtained and stored in secure data rooms, and subsequently converted into knowledge. The availability and reliability and thus the efficiency (OEE) of the system are determined in near real time from the operating states.

OEE comparisons of identically constructed systems in other lines can be used to identify the causes of different levels of efficiency. The result is steadily improved output and system availability.

The increasing amount of data leads to more precise analyses and visible correlations between relevant machine-related production and process data – plus, optimisation potential can be exploited in a targeted manner.

Intralogistic

Intelligent intralogistics enable higher productivity and delivery reliability in the modern factory. Order-controlled material logistics ensure that materials are supplied to the production lines at the right time. Supported by automated goods controls via, for example, FTS, synchronised with the warehouse data from the WMS (warehouse management system) and the order data from production, material is made available at the production facilities exactly when required. When data is processed in near real time, physical movements and the relevant flow of information can be optimally coordinated. Precise analyses allow for optimal state monitoring and goods tracking. AI-based analytics performs a preventive view of impending material shortages and can initiate corrective actions.

Quality management

Through the online validation and documentation of production and process data, sources of error can be avoided and quality improved. Comprehensive production documentation is used to trace the causes of possible quality problems back to the individual product (serialised traceability) and to analyse them precisely. With the proof of quality provided by the production and process data for your products, companies benefit from increased customer confidence and a significant competitive advantage.

Traceability

Track your components continuously along your value chain by recording all production and process data. Using a track & trace solution, data is collected from all relevant data sources, such as sensors, IT systems, plants, transport systems, etc., linked to the component and placed in a valid data storage. Via a unique ID/serial number, all relevant information on this component can be read and analysed later on, helping to identify problems quickly, reduce waste and contribute significantly to improving quality. At the same time, track & trace also allows for unambiguous traceability in the event of a problem that is detected later, and thus contributes to a reliable analysis of possible causes of faults.

Maintenance management

Machine and system maintenance is a high cost factor for companies. There is often a risk of over-maintenance. Intelligent maintenance management in the smart factory no longer follows rigid maintenance intervals but aims on the one hand for needs-based maintenance and thus cost savings and on the other hand for predictive processes. Modern maintenance management uses data correlation based on past, present and live data gained from intelligent analytical processes. As a result, it is possible to identify potential system problems that cannot be predicted using analogue methods, and to prevent them from occurring in the first place. This reduces the risk of unplanned downtime. System availability increases significantly. In turn, maintenance times and intervals as well as the associated downtime costs and operating resource costs are minimised.

Data management

A smart factory thrives on all the production areas being optimally and intelligently coordinated and networked with their machines and systems as well as the valuable data storages from which value can be created. This requires fast and user-centred pre-processing of the production and process data. Intelligent data management ensures that all data from the various and heterogeneous sources is first collected, harmonised and processed, and finally stored in a secure data memory. Supplemented by the master and transaction data from ERP and PLM, the data is available for further use in an industry-relevant structured and standardised form. Valuable knowledge can be generated from analyses and fact-based decisions and recommendations for action derived. Local data storage on the factory edge provides a high level of security even for sensitive production and process data (unrestricted data superiority). High availability is also guaranteed. Ultimately, the wealth of knowledge generated by this data remains in your own hands.